Maintaining flowability and preventing segregation in complex formwork

Increased labor costs and compromised structural integrity

Project delays that impact budgets and timelines

Water reducers (superplasticizers) offer a robust solution to these challenges. As POLLYFLEX, a leading manufacturer, we want to share our expertise to help you succeed.

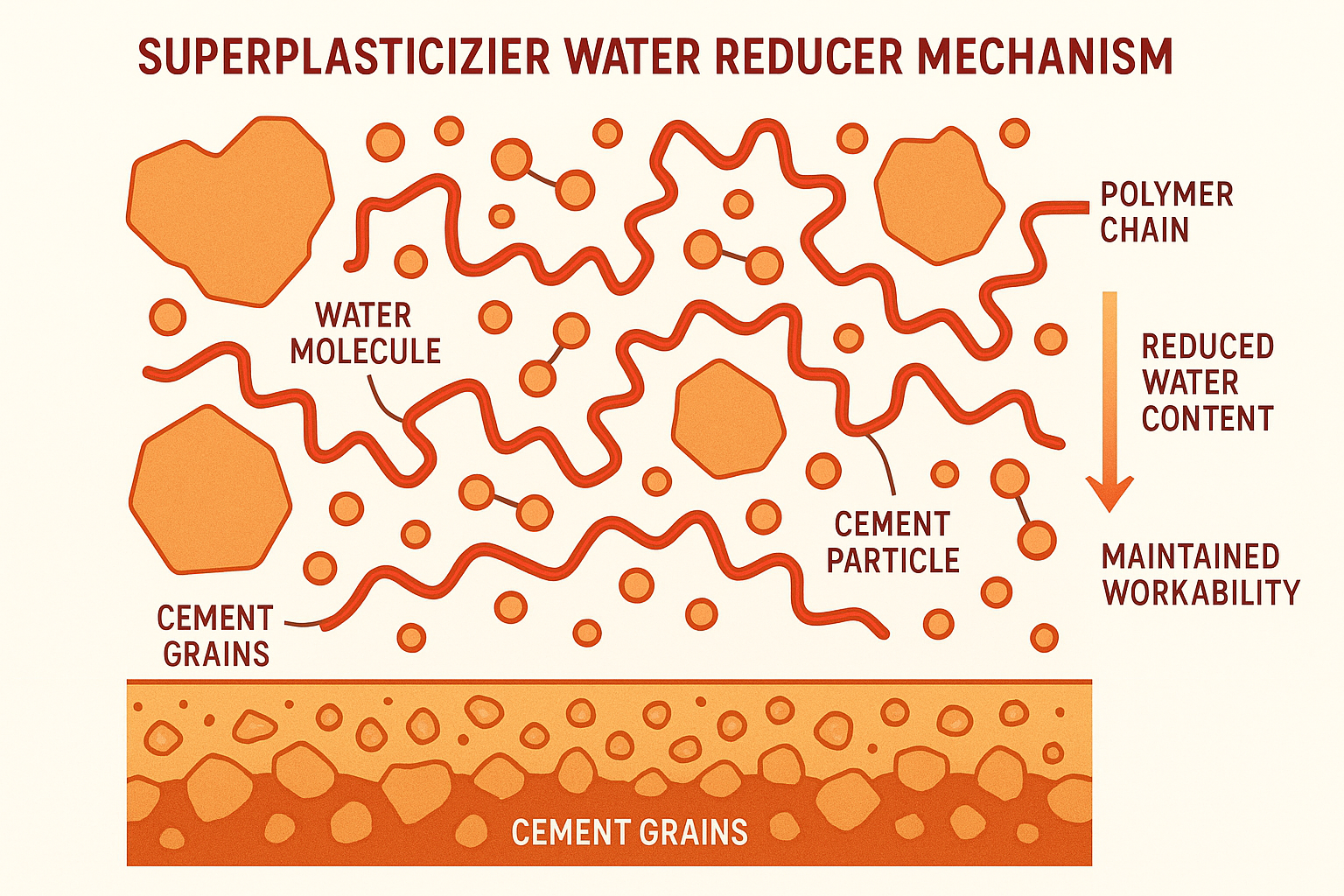

A water reducer, often referred to as a superplasticizer or high-range water reducer (HRWR), is a chemical admixture added to concrete to significantly enhance its workability without increasing the water content.

Think of it as a lubricant for concrete – it allows cement particles to slide past each other more easily, making the mix more fluid and easier to place.

These admixtures are essential in modern concrete technology, enabling the production of high-strength, durable, and easily workable concrete, particularly in applications where low water-to-cement ratios and high fluidity are required.

Microscopic view of cement particles with superplasticizer molecules

| Property | Naphthalene Superplasticizer (SNF) | Sulfonated Melamine Superplasticizer(SMF) | Polycarboxylate Superplasticizer(PCE) |

|---|---|---|---|

| Water Reduction | 15–30% | 10–20% | 30–40%+ |

| Slump Retention | Poor, significant loss | Moderate | Excellent, long-lasting |

| Strength Contribution | Moderate, general use | High early, moderate final | High early & ultimate |

| Applications | Ready-mix, bridges | Precast, panels | SCC, UHPC, complex pours |

Modern chemical plant producing high-quality PCE superplasticizers

At POLLYFLEX, we understand the critical role PCEs play in achieving superior SCC performance. Our POLLYFLEX series of polycarboxylate superplasticizers are specifically formulated to meet the diverse needs of the construction industry.

Tailored to your specific project requirements

Experienced engineers provide comprehensive support

Reliable supply and distribution worldwide

Testing and evaluation samples provided

| Product Name | Effective Content (%) | Water Reduction (%) | Slump Retention (min) | Type |

|---|---|---|---|---|

| POLLYFLEX PCE-Flake 670 | 97% ± 1 | ≥ 25 | ≥120 | Premium |

| POLLYFLEX PCE-Flake 680 | 97% ± 1 | ≥ 25 | ≥120 | Water Reduction |

| POLLYFLEX PCE-Flake 690 | 97% ± 1 | ≥ 25 | ≥120 | Slump Retention |

Note: Dosage is expressed as a percentage of cementitious materials by weight. Optimal dosage may vary depending on specific mix design and application conditions.

For general applications where moderate flowability and workability are needed. A standard PCE dosage provides adequate performance for most construction projects.

Used in complex geometries or heavily reinforced structures. Requires higher PCE dosage for exceptional flow and passing ability around reinforcement.

For high durability applications like marine environments or aggressive chemical exposures. Specialized PCEs used with other admixtures.

Key Benefit:

Reduces water content by up to 40%, leading to higher compressive strength and improved long-term durability.

Impact:

Denser concrete matrix, reduced permeability, increased resistance to freeze-thaw cycles and chemical attack.

Why it matters:

Creates stronger, longer-lasting structures, minimizing maintenance and repair costs.

Laboratory testing showing improved strength

Self-consolidating concrete flowing smoothly around reinforcement

Key Benefit:

Creates a highly fluid mix that effortlessly fills complex forms and encapsulates reinforcement without vibration.

Impact:

Reduces labor costs, speeds up construction time, and eliminates risk of honeycombing or air voids.

Why it matters:

Simplifies construction, reduces errors, and ensures consistent, high-quality results.

Key Benefit:

Maintains desired consistency and flowability of the concrete mix for extended periods.

Impact:

Provides ample time for placement, even in challenging conditions or large-scale pours.

Why it matters:

Reduces risk of cold joints, improves surface finish, and allows for more efficient construction logistics.

Time-lapse showing excellent slump retention over hours

| Factor | Considerations | POLLYFLEX Recommendation |

|---|---|---|

| Desired Slump | Higher slump requires higher dosages or more effective superplasticizers | High slump (>200mm): POLLYFLEX PCE Flake 690 |

| Concrete Strength | Higher strength requires lower w/c ratios, best achieved with PCE | High-strength (>40 MPa): POLLYFLEX PCE Flake 670 |

| Environmental Conditions | Temperature and humidity affect superplasticizer performance | POLLYFLEX PCE Flake 670 adapts to wide range of conditions |

| Formwork Complexity | Intricate formwork needs excellent flowability and slump retention | POLLYFLEX PCE Flake 680 ideal for complex formwork applications |

Separation of concrete components during placement.

Solution:

Use POLLYFLEX PCE Flake 690 with good slump retention. Adjust dosage and consider VMA for improved stability.

Water rising to the concrete surface and thus cracking.

Solution:

Reduce water content and use POLLYFLEX PCE Flake 680. Ensure proper mix design and avoid over-vibration.

Difficulty achieving desired concrete flow.

Solution:

Increase dosage, switch to PCE, or adjust mix design. Consult POLLYFLEX technical support.

Add 0.5-1.4% by weight of cementitious material following manufacturer's recommendations.

Add to mixing water or directly into mixer. Ensure thorough mixing for uniform distribution.

Proper mixing procedures

Store in original containers in dry, cool area. Protect from freezing temperatures.

Wear appropriate PPE. Avoid direct skin contact and ensure adequate ventilation.

Success Key

Always perform trial mixes to determine optimal dosage.

Best Practice

Verify compatibility with other admixtures before use.

State-of-the-art research and development laboratory facilities

At POLLYFLEX, we are committed to providing the highest quality superplasticizers. Our state-of-the-art manufacturing facility is equipped with advanced process control systems and adheres to stringent quality standards.

Developing high-performance PCE superplasticizers with enhanced slump retention

Creating sustainable and environmentally friendly superplasticizer formulations

Optimizing superplasticizer performance for specific applications

Quality control testing procedures and certification standards

Superplasticizers are indispensable for producing high-quality Self-Consolidating Concrete. POLLYFLEX offers a comprehensive range of superplasticizers tailored to meet the diverse needs of SCC applications.

Professional team ready to provide technical support and consultation

Our team of experts is available to provide technical support and help you select the right superplasticizer for your specific project requirements.

Let us help you build better, stronger, and more durable structures!