What is a Water Reducer (Superplasticizer)?

A water reducer, more technically known as a superplasticizer, is a chemical admixture meticulously formulated to enhance the properties of cementitious materials like grouting mortar. At its core, a superplasticizer is designed to increase the fluidity, or workability, of the mortar without necessitating an increase in its water content. Think of it as a "lubricant" for the cement particles, allowing them to slide past each other more easily. This seemingly simple action has profound consequences for the mortar's ultimate performance.

How Superplasticizers Work Their Magic in Grouting Mortar

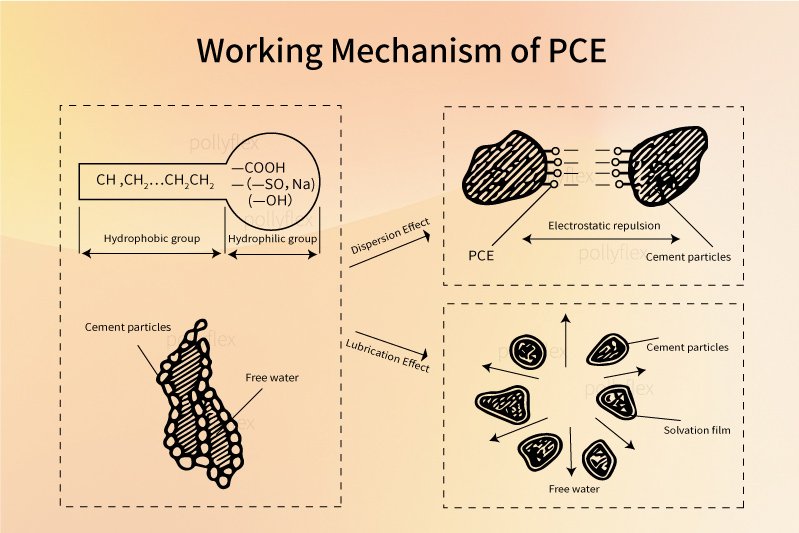

The magic of superplasticizers lies in their ability to disperse cement particles effectively. Here's how it unfolds:

Initial State:

In a typical grouting mortar mix, cement particles tend to clump together due to electrostatic forces. This clumping restricts the free flow of the mix and requires a higher water content to achieve the desired consistency.

Superplasticizer Introduction:

When a superplasticizer is introduced, its molecules are adsorbed onto the surface of the cement particles.

Electrostatic Repulsion (Traditional):

Early generation superplasticizers, like lignosulfonates or sulfonated naphthalene/melamine-formaldehyde condensates, function primarily through electrostatic repulsion. They impart a negative charge to the cement particles, causing them to repel each other.

Steric Hindrance (Modern PCEs):

Modern superplasticizers, particularly those based on polycarboxylate ether (PCE) polymers, employ a more sophisticated mechanism: steric hindrance. PCE molecules have long, branched chains that extend outwards from the cement particle surface. These chains physically prevent the particles from approaching each other closely.

Dispersed Particles:

Regardless of the mechanism (electrostatic or steric), the result is the same: the cement particles are effectively dispersed, breaking down the clumps.

Enhanced Workability & Reduced Water:

This dispersion dramatically increases the workability of the mortar. The mix becomes more fluid and easier to place, even with a significantly reduced water content (typically 15-40%). The lower water-to-cement ratio then leads to higher strength and improved durability. This water reduction is crucial for achieving high-performance grouting mortar.

Result:Superplasticizers, particularly polycarboxylate ethers (PCE), improve the performance of grouting mortars by reducing the water-to-cement ratio. This leads to enhanced flowability, higher early strength, and greater durability, making the mix more workable with lower water content.

Learn more about superplasticizers and their benefits on Wikipedia.

Application Grades and Their Specific Needs

Superplasticizers aren't a one-size-fits-all solution. Their application in grouting mortar varies depending on the desired performance characteristics and the specific grade of mortar:

Standard Grouting Mortar:

In standard applications, superplasticizers primarily improve workability and reduce the risk of segregation. This leads to easier application and a more consistent finish.

High-Performance Grouting Mortar:

For demanding applications requiring high strength and durability, superplasticizers are essential. They enable the creation of low water-to-cement ratio mixes, leading to significantly enhanced mechanical properties.

Self-Consolidating Grouting Mortar (SCGM):

SCGM is designed to flow easily into confined spaces without requiring vibration. Superplasticizers are crucial for achieving the necessary fluidity and stability in these mixes.

Unlock the Power of Enhanced Grouting Mortar: Key Advantages

Incorporating a superplasticizer into your grouting mortar formulation unlocks a wealth of benefits:

Enhanced Workability:

Achieve effortless placement and superior flow characteristics.

- • Increased fluidity for easier application.

- • Improved penetration into narrow gaps and complex geometries.

- • Reduced effort required for mixing and placement.

Superior Strength Development:

Optimize your mortar's compressive and flexural strength.

- • Lower water-to-cement ratio leads to denser and stronger mortar.

- • Faster strength gain for quicker project turnaround.

- • Enhanced long-term durability and resistance to cracking.

Reduced Permeability:

Minimize water ingress and protect against corrosion.

- • Denser microstructure reduces permeability to water and chlorides.

- • Enhanced resistance to freeze-thaw cycles.

- • Improved long-term performance in harsh environments.

Improved Bond Strength:

Create a stronger and more reliable bond between the mortar and the substrate.

- • Increased surface contact area due to improved flow.

- • Reduced shrinkage and cracking, minimizing bond stress.

- • Enhanced resistance to tensile and shear forces.

Extended Working Time:

Maintain workability for longer periods, reducing waste and improving efficiency.

- • Improved slump retention for consistent performance throughout the application process.

- • Reduced risk of premature stiffening or setting.

- • Greater flexibility in scheduling and application.

As stated by the European Federation of Concrete Admixtures Associations (EFCA), superplasticizers are high-range water reducers crucial for achieving superior concrete performance.

Pollyflex: Your Partner in Grouting Mortar Excellence

At Pollyflex, we understand the critical role that high-quality admixtures play in achieving superior grouting mortar performance. Our Pollyflex Superplasticizers are meticulously engineered to deliver exceptional results across a wide range of applications.

| Property | Naphthalene Superplasticizer | Sulfonated Melamine Superplasticizer | Polycarboxylate Superplasticizer |

|---|---|---|---|

| Water Reduction | 15-20% | 20-25% | 25-40% |

| Workability Enhancement | High | Very High | Extremely High |

| Slump Retention | Moderate | Good | Excellent |

| Dosage (by weight of cement) | 0.2-0.8% | 0.3-1.0% | 0.1-0.5% |

| Main Applications | General Grouting | High-Strength Grouting | Self-Consolidating Grouting |

We offer free samples, global shipping, and customized formulation services to meet your specific needs.

Choosing the Right Superplasticizer for Your Needs

Selecting the optimal superplasticizer depends on several factors, including the desired performance characteristics, the type of cement used, and the environmental conditions.

| Application Scenario | Cement Type | Desired Workability | Recommended Pollyflex Grade |

|---|---|---|---|

| General Purpose Grouting | Ordinary Portland | Overall Balanced Performance | Pollyflex PCE Flake 670 |

| High-Performance Concrete | Ordinary Portland | High Water Reduction, Superior Flow | Pollyflex PCE Flake 680 |

| Grouting for Vertical Applications | Low Alkali Portland | Excellent Slump Retention, Anti-Sagging | Pollyflex PCE Flake 690 |

Troubleshooting: Common Grouting Mortar Problems and Solutions

| Problem | Cause | Pollyflex Solution |

|---|---|---|

| Excessive Shrinkage Cracking | High water content, rapid drying, poor curing conditions | Pollyflex PCE Flake 670: Balanced performance, reduces water content, and helps prevent shrinkage cracking |

| Poor Bond to Substrate | Inadequate surface preparation, low flow, insufficient adhesion | Pollyflex PCE Flake 680: High water reduction and improved flow for enhanced bonding with substrates |

| Premature Stiffening | High temperature, reactive aggregates, fast-setting mix | Pollyflex PCE Flake 690: Excellent slump retention, prevents premature stiffening in hot conditions |

| Low Workability | Low water content, poor mix design, or difficult-to-mix materials | Pollyflex PCE Flake 680: Improves workability while maintaining low water content |

| Cracking Under Load | Inadequate strength development, low cement content, or poor mix ratio | Pollyflex PCE Flake 690: Enhances cohesion and early strength development under load |

Instructions for Use and Important Considerations

Dosage:

Carefully determine the optimal dosage of Pollyflex superplasticizer based on your mix design and desired performance. Refer to the product data sheet for recommended dosage ranges.

Mixing:

Add the superplasticizer to the mixing water before adding the cement and aggregates. Ensure thorough mixing to achieve uniform dispersion.

Placement:

Place the grouting mortar promptly after mixing to maximize workability and minimize the risk of segregation.

Curing:

Properly cure the grouting mortar according to industry best practices to ensure optimal strength development and durability.

Key Success Tip: Always conduct trial mixes to verify the compatibility of the superplasticizer with your specific materials and application conditions.

Ordering and Sample Information

| Specification | Details |

|---|---|

| Packaging | 25 kg bags, 1000 kg bulk bags |

| Minimum Order Quantity (MOQ) | 1 metric ton |

| Lead Time | 7-14 days |

| Payment Terms | T/T, L/C |

| Shipping Options | Sea, Air, Land |

| Sample Policy | Free samples available upon request |

Quality Control and R&D Excellence

At Pollyflex, we are committed to providing the highest quality products and technical support. Our state-of-the-art manufacturing facilities ensure consistent product performance through advanced process control systems.

Our research and development team focuses on developing advanced superplasticizers with enhanced characteristics like improved slump retention, increased early strength, and reduced shrinkage. We also invest in environmentally friendly products with minimal impact. Our R&D efforts include:

- New PCE polymers with superior performance.

- Optimizing formulations for specific applications.

- Reducing environmental impact of products.