Transforming Modern Construction Challenges

In the demanding world of modern construction, achieving both exceptional workability and superior mechanical properties in High-Performance Concrete (HPC) presents a significant technical challenge for engineers and procurement professionals.

Traditional concrete mixes often suffer from limited flowability when attempting high strength, leading to placement difficulties, increased labor costs, and potential quality compromises like honeycombing or segregation. Such limitations can severely impact project timelines, structural integrity, and long-term durability.

This is where high-range water reducers, commonly known as superplasticizers, offer a revolutionary solution, fundamentally transforming concrete rheology and performance by enhancing flowability and strength simultaneously.

What are Water Reducers (Superplasticizers)?

Principle, Structure, Properties

Water reducers, specifically high-range water reducers (HRWRs), or superplasticizers, are a class of chemical admixtures designed to dramatically increase the fluidity of concrete mixes without adding extra water.

Unlike conventional plasticizers that offer moderate water reduction (around 5-15%), superplasticizers can achieve water reductions of 20-30% or even more, hence their designation as "high-range."

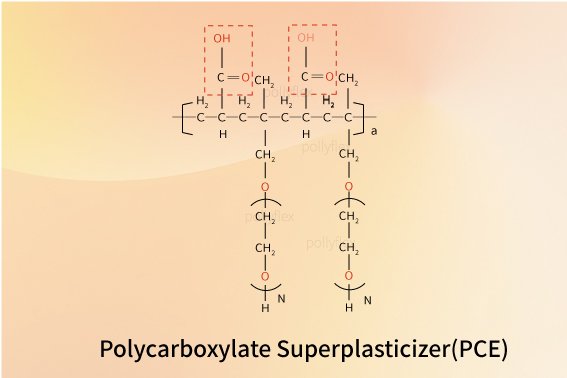

At their core, superplasticizers are organic polymers with a unique molecular structure. They consist of a long polymer backbone with anionic or non-ionic side chains. When added to a concrete mix, these molecules adsorb onto the surface of cement particles.

How It Works:

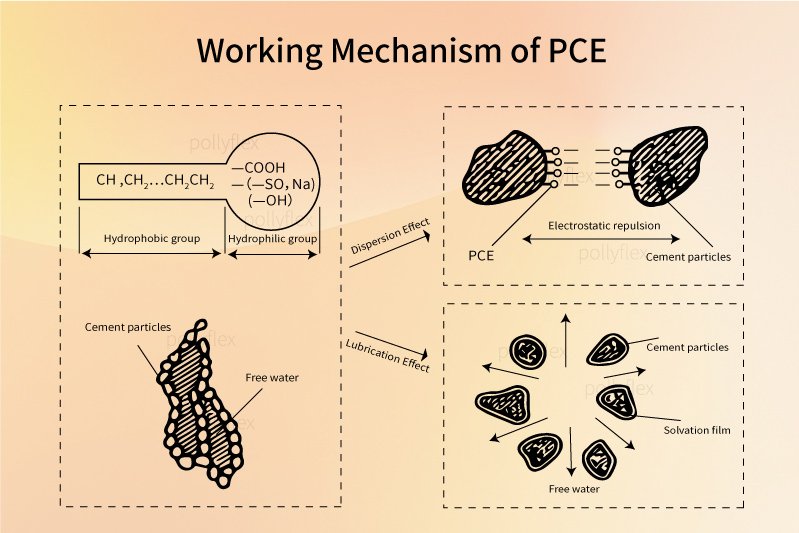

Imagine cement particles as tiny magnets, naturally clumped together. Superplasticizers act like dispersants, creating electrostatic repulsion or steric hindrance between particles. This deflocculation releases trapped water, making it available for lubrication and improving flowability while enabling more efficient hydration.

Key Mechanism

- Particle Dispersion

- Water Liberation

- Enhanced Flowability

- Strength Optimization

PCE Polymer Chain

Advanced molecular architecture

Dispersion Mechanism

Cement particle deflocculation process

Common Types of Superplasticizers

High-Range Water Reducers Comparison

ZOVAE: Leading the Way with POLLYFLEX PCE Water Reducer

At ZOVAE, we understand the critical demands of modern construction. Our flagship high-range water reducer, POLLYFLEX PCE, is engineered to push the boundaries of concrete performance, delivering unparalleled workability, strength, and durability for your most challenging projects.

Key Parameters & Features of POLLYFLEX

POLLYFLEX PCE Product Selection Guide

Comprehensive Advantages of PCE Superplasticizers

Benefits that extend far beyond simple water reduction, translating into superior concrete performance and enhanced construction efficiency

Superior Water Reduction

Achieves up to 40% water reduction, enabling ultra-low water-to-cement ratios crucial for UHPC applications.

Excellent Slump Retention

Maintains fluidity for extended periods, eliminating on-site water addition and improving logistics.

Enhanced Strength & Durability

Higher compressive strength, improved resistance to aggressive environments, reduced shrinkage.

Broad Compatibility

Works effectively with diverse cements and optimizes supplementary cementitious materials performance.

Sustainable Construction

Reduced cement consumption, lower water demand, extended concrete lifespan, improved energy efficiency.

Superior Surface Finish

Smoother, denser surfaces with reduced bug holes and voids, minimizing finishing work requirements.

Strength & Durability Enhancement

Comparative strength development and durability metrics

Environmental Benefits

Carbon footprint reduction and resource conservation

How to Choose the Right ZOVAE POLLYFLEX Model

Selecting the appropriate superplasticizer is crucial for optimizing concrete performance and project success

Selection Criteria

Target Concrete Properties

- • Strength: 40-100+ MPa compressive strength

- • Workability: Standard pumpable vs. SCC properties

- • Durability: Low permeability requirements

- • Setting Time: Normal, accelerated, or retarded

Cementitious Materials

- • Cement Type: OPC Type I, II, V variations

- • SCMs: Fly ash, slag, silica fume compatibility

- • Dosage Impact: SCM affects effectiveness

Environmental Conditions

- • Temperature: Ambient and concrete temperature effects

- • Humidity: Influence on workability retention

- • Transport Time: Distance and duration requirements

Application Examples

High Performance Concrete

Self-consolidating concrete applications requiring superior flowability and strength characteristics.

Problems and Solutions

Common concrete challenges and how POLLYFLEX provides effective solutions

High Strength vs. Workability

Achieving high strength while maintaining workability for proper placement without segregation.

POLLYFLEX Solution:

Enables up to 35% water reduction without compromising slump, ensuring uniform distribution and preventing segregation.

Rapid Slump Loss

Loss of workability during transport, especially in hot weather conditions or long distances.

POLLYFLEX Solution:

Superior slump retention for 60-90+ minutes, maintaining workability until placement completion.

Compatibility Issues

Inconsistent performance with different cement types and admixture combinations.

POLLYFLEX Solution:

Excellent compatibility across all cement chemistries with comprehensive technical support.

Need Help Solving Your Concrete Challenges?

Our technical experts are ready to help you select the right POLLYFLEX solution for your specific project requirements.

Get Technical SupportUsage Instructions & Important Notes

Professional guidelines for optimal ZOVAE POLLYFLEX performance and safety

Recommended Usage

Dosage

Optimal dosage ranges from 0.5% to 2.0% by weight of cementitious material. Exact dosage determined by trial mixes.

Mixing

Add with batch water during initial mixing. For optimal performance, consider delayed addition after initial component mixing.

Dispersion

Ensure adequate mixing time (60-90 seconds) after POLLYFLEX addition for uniform dispersion.

Important Notes

- • Trial Mixes are Crucial: Always conduct preliminary trials with site-specific materials

- • Equipment Cleaning: Thoroughly clean when switching between different admixture types

- • Storage Conditions: Store between 5°C-35°C, protect from freezing

- • Safety: Refer to MSDS for detailed safety information and use appropriate PPE

Step-by-Step Mixing

Proper addition and mixing sequence

Storage Guidelines

PPE requirements and proper storage

Ordering and Sample Information

| Aspect | Details |

|---|---|

| Packaging | 25kg bags |

| MOQ | 1 Ton or as per request |

| Lead Time | 7-14 business days from order confirmation |

| Payment Terms | T/T, L/C, and more. |

| Shipping | Global shipping - Sea, Air, or Land |

| Sample Policy | Free samples available upon request |

Quality Control and Research & Development Excellence

Our commitment to excellence is deeply rooted in robust Quality Control protocols and forward-thinking R&D strategy

Rigorous Quality Control

- • Adherence to ASTM C494 and EN 934-2 international standards

- • Raw material inspection and in-process monitoring

- • Comprehensive final product testing

- • Full batch traceability from raw material to finished product

Innovative R&D

- • Advanced analytical techniques (GPC, FTIR, NMR)

- • Customized solutions for unique project challenges

- • Sustainability focus with eco-friendly formulations

- • Continuous improvement based on field feedback

Unlock the Future of Concrete Performance

ZOVAE POLLYFLEX represents the pinnacle of superplasticizer technology, offering advanced PCE-based solutions for consistent, reliable, and superior performance. Ready to elevate your concrete performance to new heights?

Contact POLLYFLEX today to discuss your specific requirements and optimize your mix designs for long-term project success