Advanced Concrete Solution for Superior Water Reduction, Workability and Durability

PCE Superplasticizer Flake 670 represents the pinnacle of POLLYFLEX commitment to innovative polymer solutions for the construction industry. This premium polycarboxylate ether (PCE) superplasticizer in flake form delivers exceptional performance for concrete applications, offering significant advantages over traditional liquid superplasticizers.

Developed through POLLYFLEX expertise in flexible materials and polymer science, PCE Superplasticizer Flake 670 is engineered to meet the demanding requirements of modern concrete production, particularly in challenging environments and high-performance applications.

Advanced manufacturing technique creates high-performance concrete admixture with precisely tailored molecular structures for optimal dispersing efficiency and slump retention.

POLLYFLEX PCE Superplasticizer Flake 670 is synthesized through sophisticated free-radical copolymerization of unsaturated polyether macromonomers.

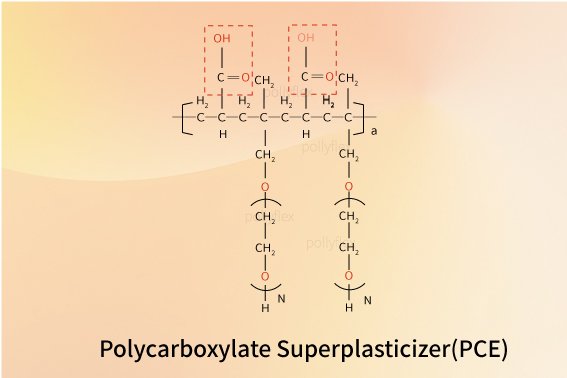

The unique "comb" structure with polycarboxylic acid backbone and polyethylene oxide side chains enables superior dispersing efficiency.

Comb-like architecture with electrostatic repulsion and steric hindrance mechanisms

The flake form of POLLYFLEX PCE Superplasticizer 670 offers substantial practical benefits over liquid alternatives:

The solid form significantly reduces shipping weight and volume, leading to lower freight expenses and reduced carbon footprint.

With minimal moisture content, the flake form resists degradation and maintains efficacy for longer periods than liquid counterparts.

No need for specialized storage tanks or concerns about freezing in cold climates.

The dry form allows for more accurate measurement and incorporation into concrete mixes.

When incorporated into concrete mixtures, POLLYFLEX PCE Superplasticizer Flake 670 delivers:

Achieves water reduction rates exceeding 25%, allowing for lower water-to-cement ratios while maintaining workability.

Creates highly flowable concrete mixes without segregation or bleeding.

The efficient dispersion of cement particles promotes more complete hydration, resulting in higher compressive strengths.

Maintains concrete workability for longer periods, even in hot weather conditions.

Works effectively with fly ash, silica fume, and GGBS, supporting sustainable concrete production.

Superior strength & durability

No vibration required

Fast production cycles

Calculate 0.2% to 0.8% by weight of cementitious materials. Exact dosage determined through trial mixes for optimal performance.

Dissolve PCE flakes completely in water to create a homogeneous solution before adding to the concrete mixture.

Add prepared solution after initial wetting of aggregates and cement, but before final water addition for uniform distribution.

Ensure thorough mixing for at least 90 seconds after addition to achieve uniform distribution and optimal performance.

Accurate measurement ensures consistent performance

Proper sequence maximizes effectiveness

Superior concrete performance guaranteed

Our expert team provides comprehensive support for dosage optimization and mixing procedures to ensure optimal concrete performance.

Contact Our Technical TeamAdvancing sustainable construction through innovative polymer technology and environmental responsibility

POLLYFLEX PCE Superplasticizer Flake 670 contributes to more sustainable construction practices through innovative design and responsible manufacturing.

Lower transportation emissions due to concentrated flake form and reduced shipping volume

Enables concrete production with lower cement content while maintaining performance

Creates longer-lasting structures, reducing repair and replacement needs

Despite its premium nature, POLLYFLEX PCE Superplasticizer Flake 670 delivers compelling economic benefits through operational efficiency and long-term value.

Lower shipping and storage expenses compared to liquid alternatives

Improved workability reduces placement and finishing time

Enhanced durability translates to lower life-cycle costs

POLLYFLEX PCE Superplasticizer Flake 670 represents a holistic approach to sustainable construction, delivering environmental benefits while maintaining economic viability.

Reduced emissions, optimized cement usage, enhanced durability

Cost optimization, improved efficiency, long-term value

Superior quality, enhanced durability, consistent results

Comprehensive testing and real-world applications demonstrate the superior performance of POLLYFLEX PCE Superplasticizer Flake 670

Extensive testing conducted by ZOVAE's R&D department has demonstrated superior performance compared to conventional superplasticizers.

Achieved 28% water reduction while maintaining equivalent slump performance

15% higher early strength (24h) and 22% higher 28-day strength vs reference mixes

Enhanced resistance to chloride penetration and freeze-thaw cycles per ASTM standards

Successfully employed in numerous challenging construction projects worldwide, demonstrating exceptional real-world performance.

High-strength concrete with exceptional workability for complex structures

Extreme climatic conditions and demanding performance requirements

Optimized production cycles and enhanced quality control

Extended setting times and controlled strength development

Comprehensive data analysis demonstrates consistent superior performance across multiple testing parameters

Compared to conventional superplasticizers

28-day compressive strength improvement

Extended workability duration

Global applications performance

ZOVAE's POLLYFLEX PCE Superplasticizer Flake 670 demonstrates excellent compatibility with:

However, compatibility testing is recommended when using with air-entraining admixtures or in specialized applications.

ZOVAE POLLYFLEX provides comprehensive technical support for PCE Superplasticizer Flake 670 users:

PCE Superplasticizer Flake 670 represents ZOVAE's commitment to developing innovative, high-performance solutions for the construction industry. By combining advanced polymer chemistry with practical application knowledge, ZOVAE has created a premium concrete admixture that addresses the challenges of modern construction while offering logistical, economic, and environmental benefits.

For construction professionals seeking to optimize concrete performance, reduce costs, and enhance sustainability, ZOVAE's PCE Superplasticizer Flake 670 provides a scientifically advanced solution backed by comprehensive technical support. As concrete technology continues to evolve, ZOVAE remains at the forefront, delivering polymer innovations that transform the built environment.

For technical support, custom solutions, or to learn more about ZOVAE's complete range of concrete admixtures and polymer products, contact our customer service team or visit our website today.